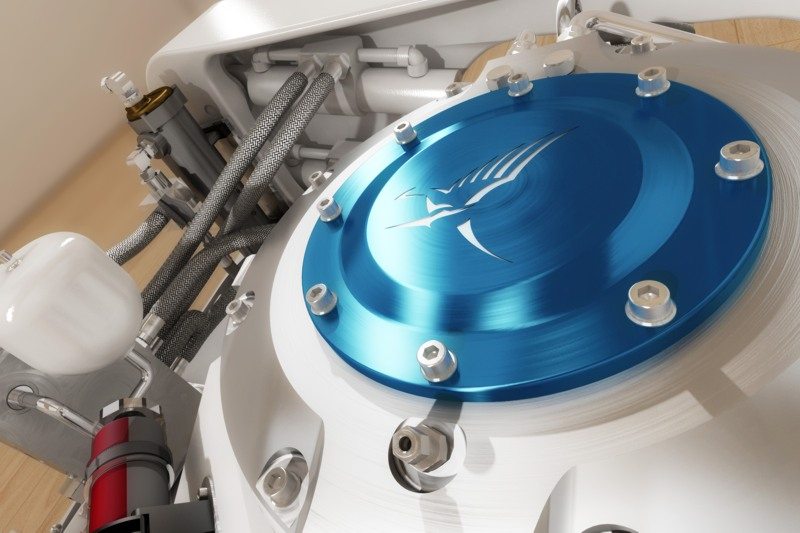

VEEM offers flexibility in propeller designs that no other manufacturer can match. Our technologically advanced manufacturing and in-house alloying process allows a custom propeller design to be supplied for each vessel application, with no impact to price or lead time.

VEEM Propellers offer a variety of material specifications, including aluminium and manganese bronzes, nickel aluminium bronzes (NiBrAl) and stainless steel. Each alloy is modified in house to meet all the chemical and mechanical requirements of the various class societies.

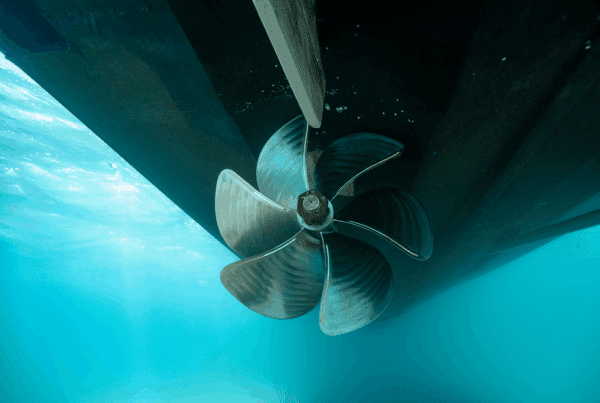

Due to its high strength properties, the most commonly used alloy for VEEM Propellers is nickel aluminium bronze. This particular bronze presents the following benefits;

- high corrosion resistance

- high resistance to cavitation and wear

- high resistance to biofouling

- easily repairable

- good anti-galling properties

In some circumstances, often to meet the requirements of the customer, VEEM will produce propellers in other alloys/materials such as stainless steels and manganese bronze.

Stainless propellers are generally requested for extreme wear, ice waters or very high-speed vessel as the material has higher strength properties.

More information about the VEEM Propeller range can be found on our website or by contacting a VEEM representative.