Faster. Less fuel. Smaller carbon footprint. The new VEEM Extreme propulsion system already demonstrates 18.1% reduction in fuel burn (and that’s just with the propeller and rudder).

Global marine technology leader VEEM Ltd has today announced the launch of the most efficient inboard propulsion system ever released: the VEEM Extreme propeller range, twisted rudder and fully flow-aligned shaft line package – engineered from the propeller tip to the brackets for maximum performance and efficiency.

With all on board results witnessed by Lloyd’s Register, these new releases are not incremental improvements. They represent a generational shift in marine propulsion efficiency: faster, more fuel efficient and significantly lower in emissions.

“This changes everything,” said Mark Miocevich, VEEM’s Managing Director. “We’ve engineered the most efficient inboard shaft driven propulsion system, using conventional propellers, the world has ever seen. We have meticulously tested all components in the real world environment on our 64 foot test vessel and have the data to prove it.”

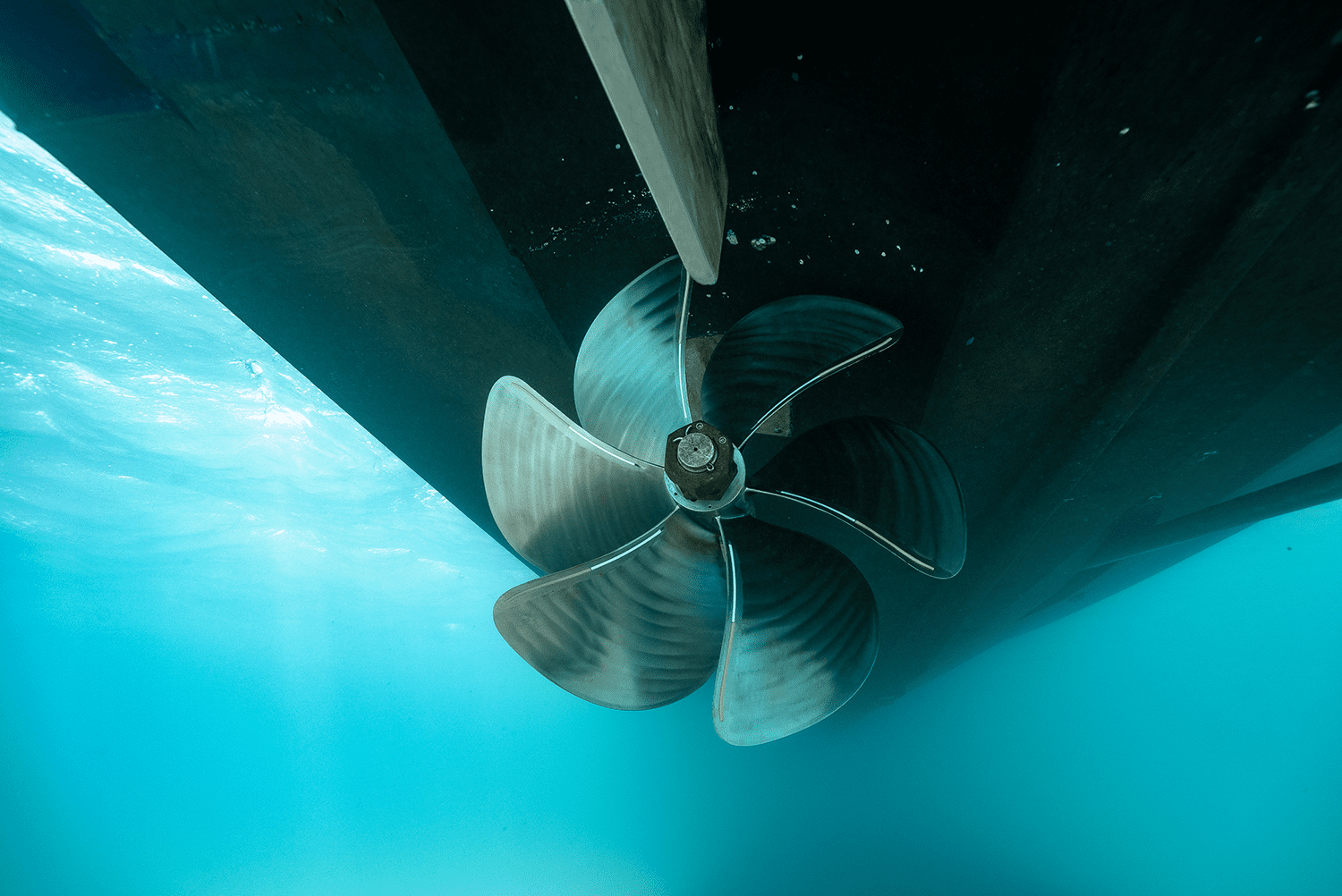

Introducing the VEEM Extreme Propeller

At the centre of this advancement is the VEEM Extreme propeller, manufactured from a proprietary, high-tensile, high-strength alloy that enables thinner blade profiles and better performance. VEEM Extreme propellers exceed ISO S-Class tolerance standards with full CNC machining over every square mm of the propeller and undergo more complex manufacturing due to the nature of the alloy.

The result is a propeller that is thinner, stronger and more fuel efficient, resulting in efficiency gains, reduced carbon footprint and speed gains beyond VEEM’s already world-leading fully CNC machined NiBral propeller range.

Controlled, witnessed trials aboard VEEM’s 64 foot Open Sport Convertible compared industry standard, Class 1 hand profiled propellers, with the current VEEM fully CNC machined NiBral propellers and the new VEEM Extreme propellers, which verified the following results:

Compared with an industry-standard, Class 1 propeller, the new VEEM Extreme Propellers delivered an 11.9% reduction in fuel burn and carbon footprint with a top speed improvement of 3.36 knots, to 43.05 knots.

They also demonstrated improvements in efficiency and speed over the current VEEM fully CNC machined NiBral propellers, with a reduction of 6.2% in fuel burn and speed improvements of 0.89 knots.

The VEEM Extreme flow-aligned rudder and shaft line system

Integrating with the VEEM Extreme propeller is the complete, flow-aligned shaft package, which includes

- VEEM Extreme flow-aligned rudder with NACA sections manufactured in the VEEM Extreme alloy, offering 72% less drag than a standard parallel plate rudder commonly used in the marine industry. Testing has already verified a further 0.25 knot increase in speed using the VEEM Extreme flow-aligned rudder and further 6.2% reduction in fuel burn.

- VEEM Extreme V and P brackets also designed in the VEEM Extreme material

- VEEM Extreme shaft that utilises a proprietary registered design – part taper, part spline to attach to the propeller and coupling reducing stress by 20% over a standard shaft and keyway design.

Together, the VEEM Extreme propulsion system combines to deliver an 18.1% reduction in fuel burn utilising the rudder and propeller alone with further shaft and bracket testing results due to be released soon.

Manly Fast Ferries Adopt VEEM Extreme in Witnessed Trial

The VEEM Extreme propeller has been tested as part of a long-term project aimed at reducing emissions, improving fuel efficiency, and modernising Sydney’s public ferry network.

In October 2025, a live trial of VEEM Extreme propellers was conducted on an Manley Fast Ferries vessel, with results witnessed and verified by Deloitte. The test demonstrated an 8% reduction in fuel consumption over a comparative hull with current VEEM NiBral propellers, confirming VEEM’s earlier Lloyd’s Register–witnessed sea trial data and validating the VEEM Extreme hypothesis.

This collaboration marks the first external testing of this product and demonstrates how VEEM is helping the maritime sector move toward a cleaner, more efficient future. Manly Fast Ferries is now planning to convert 6 more vessels to VEEM Extreme propellers over the next 18 months, with contract negotiations underway. Manly Fast Ferries have also advised they intend to conduct a trial with the VEEM Extreme rudder with a view to including the VEEM Extreme rudder as part of the VEEM Extreme propeller conversions mentioned above.

The VEEM Extreme propulsion system is available to order now with a 6 month lead time. Contact props@veem.com.au for further enquiries.