During the development of its marine access solutions, Damen has demonstrated the value of the group’s philosophy of listening to its clients, and to the market in general. This enables it to identify changes in the offshore industry, both those happening now and those anticipated in the future, and to modify and adapt its products accordingly. Damen takes this process a step further by, instead of acting alone, working in a spirit of collaboration with industry partners to develop fully integrated solutions that meet the needs of its customers.

POOLING KNOWLEDGE, INTEGRATING SOLUTIONS

As Damen Business Development Manager David Stibbe said, “By working together with our partners and pooling our respective, specialist knowledge sets, Damen can provide its clients with so much more than just a vessel. We are able to act as a marine access knowledge centre, capable of delivering completely integrated solutions using proven technologies that are both safe and cost-efficient.” An example of this type of collaboration is the work that Damen has undertaken with Australia-based VEEM Gyro to build on the successful installation of an Ampelmann L-type motion-compensated gangway on board a

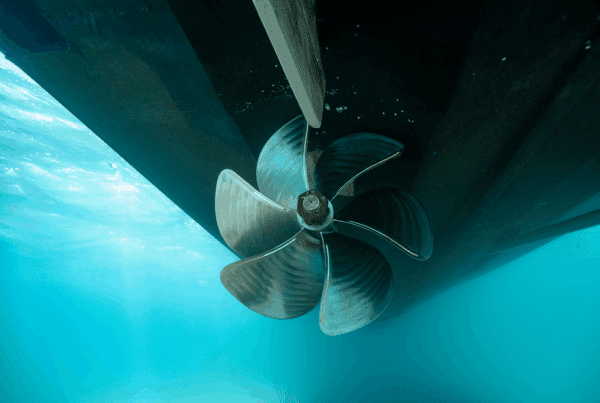

Damen Fast Crew Supplier (FCS) 5009. The objective; to use VEEM’s stabilizers to further improve the safety and comfort of what is already an innovative marine access solution. Founded 50 years ago, VEEM has great experience in developing innovative engineering for the marine sector as well as manufacturing specialist components for the aerospace and oil & gas industries. It made its name by transforming fixed pitch propeller technology for leisure craft with its Interceptor propellers which allow the propeller’s pitch to be altered at any time by a diver. With that successfully launched, in 2011 VEEM took on a new development challenge by acquiring the rights to a marine gyrostabilizer technology that today underpins its stabilizer range. VEEM employs around 180 people and is listed on the Australian Stock Exchange.

UNION OF TWO TECHNOLOGIES

VEEM and Damen collaborated from the outset, with VEEM providing performance simulation modules to support Damen’s investment in numerical simulations of gyro stabilizers for its range of monohull vessels. Damen’s relatively slender Sea Axe hull forms are particularly suited to roll stabilisation using gyro stabilizers. “It has been very pleasing to see the partnership between Damen and VEEM develop a completely new offering to the offshore marine service market for fast crew transfer,” says Paul Steinmann, Product Manager at VEEM.

What is even more exciting about the Damen/VEEM relationship is the potential for further optimisation of the already excellent seakeeping behaviour of Damen’s entire range of Sea Axe platforms by virtually eliminating rolling motions.

The integration of the Damen Sea Axe hull with VEEM’s stabilization technology has many potential applications with its combination of stability, propulsive efficiency, station keeping, and robust simple operation. Vessel classes that would derive major benefits include both offshore and coastal patrol vessels, supply vessels and research vessels, as well as crew transfer vessels and perhaps even autonomous vessels that Damen may develop in the future. With Damen and VEEM sharing a strong focus on technology and innovation, as well as a culture of manufacturing excellence, the possibilities are extensive.

A PROVEN CONCEPT

The benefits of the partnership went on display to the maritime industry at a recent event staged by Damen in cooperation with VEEM and Ampelmann. On show was a Damen FCS 5009 with an Ampelmann L-type gangway and twin VEEM VG260SD stabilizers. Delegates from vessel-operating companies from around the world had the opportunity to sail aboard the FCS 5009 and witness the integrated systems in operation.

The stabilizers proved to be very effective, with the roll motion of the vessel reduced by between 35 and 40%, as specified, when holding steady alongside an offshore installation. Damen’s David Stibbe observed: “One of the many interesting features of the event was demonstrating the gyro stabilizers being switched on and off at the push of a button. This enabled guests to appreciate the positive effect they have on the vessel’s roll motion.

“The benefits that the stabilizers offer for both comfort and safety are already being applied to the designs for the next generation of Damen Fast Crew Suppliers,” he continued. “Our new FCS 7011 will feature the larger VEEM VG1000SD unit, which will achieve a roll reduction of up to 70% in 2.5m significant wave heights.”

VEEM Chairman Brad Miocevich, who attended the trials, added: “The performance of the VG260SDs were absolutely as predicted and exceeded Damen’s expectations. We are very excited to receive Damen’s confirmation that they would now like to proceed to the purchase phase and confirm commercial requirements and delivery dates for us to supply VEEM’s largest gyrostabilizer, the VG1000SD, for the new Damen FCS 7011.”

With the increasing understanding that increased further safety and comfort on board high performance workboats makes economic sense as well as enhancing an operator’s effectiveness, the partnership between Damen and VEEM has been well-timed indeed. And with marine access solutions set to be a major growth area in the years ahead, the two companies look forward to an extended and fruitful period of mutual cooperation.

Source: DAMEN Offshore & Gas Magazine