Propeller manufacturing has come a long way with technology in the last few decades. So many elements of the manufacturing process have been redefined to include technology advances that have continuously lead to better quality propellers and better vessel performance.

Whilst many propeller manufacturers are still utilising wooden pattern techniques as part of the manufacturing and casting process, we have found the biggest impact on the final performance of a propeller to be in the ability to create propeller moulds without patterns.

When utilising propeller patterns (for example full metal patterns or wooden patterns), manufacturers are limited to an ‘off the shelf’ range of propeller sizes and designs with limited options to change the principle geometry. These minimal changes don’t always suit the application and they therefore miss out on the optimum design process, which provides the biggest gain in propeller performance and smoothness.

When utilising patternless moulding, the precise shape and size of the propeller is cut directly into special resin sand which forms a two-part mould that metal is then poured into. This technology enables a number of things:

- Propellers can be custom designed without manufacturing constraint

- Propellers precisely match the requirements of the vessel application

- Bespoke designs can be created quicker

- The entire design to casting process is quicker

- Any principle geometry can be utilised

The technology behind pattern-less moulding also ensures that identical replacements can be made of propellers that are accurate within microns.

Patternless moulding on performance

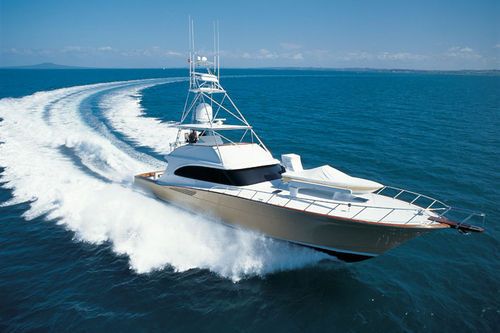

When you are after high-performance, efficiency and smoothness, your propellers need to be designed to suit your your vessel’s characteristics and operating conditions. Patternless moulding means every single propeller is bespoke designed. Our design team works closely with you to design and test propellers before they are sent out to the in-house manufacturing facility for production – and they are guaranteed to perform.

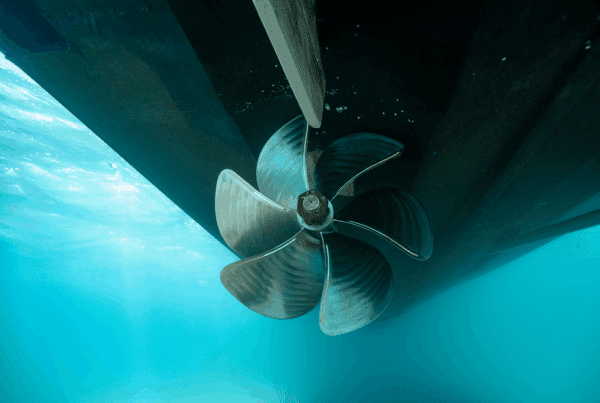

Patternless moulding on Cavitation

Marine Propeller Cavitation is one of the propeller industries’ largest concerns when it comes to performance and efficiency. The issue is not always diagnosed properly or treated effectively. Due to the differing vessel geometry, sea conditions, propeller size and shape requirements and speeds – cavitation is experienced differently and to different extents by every vessel. Pattern-less moulding means cavitation resistance technology can be applied to suit the category of cavitation you uniquely experience to eliminate the effects.

VEEM Propellers are all custom made using pattern-less moulding from 500mm (20″) – 4.6m (15′). They achieve speeds of up to 50knots with little to no cavitation. Use our propeller calculator today.