Using your VEEM Propeller Puller

| Part Number | Shaft Diameter | Max Torque (lbf.ft) |

| SAE 150 | 1.50″ | 13 |

| SAE 175 | 1.75″ | 16 |

| SAE 200 | 2.00″ | 16 |

| SAE 225 | 2.25″ | 23 |

| SAE 250 | 2.50″ | 32 |

| SAE 275 | 2.75″ | 38 |

| SAE 300 | 3.00″ | 38 |

| SAE 350 | 3.50″ | 60 |

| SAE 375 | 3.75″ | 76 |

| SAE 400 | 4.00″ | 76 |

| SAE 450 | 4.50″ | 133 |

| SAE 500 | 5.00″ | 133 |

| SAE 550 | 5.50″ | 133 |

| SAE 600 | 6.00″ | 133 |

1. Preliminary Setup.

Before installation, ensure all preliminary tasks are completed, such as cleaning the shaft, checking key clearance, and blueing. Once ready, place the propeller onto the shaft with the key in place, and push it firmly into position.

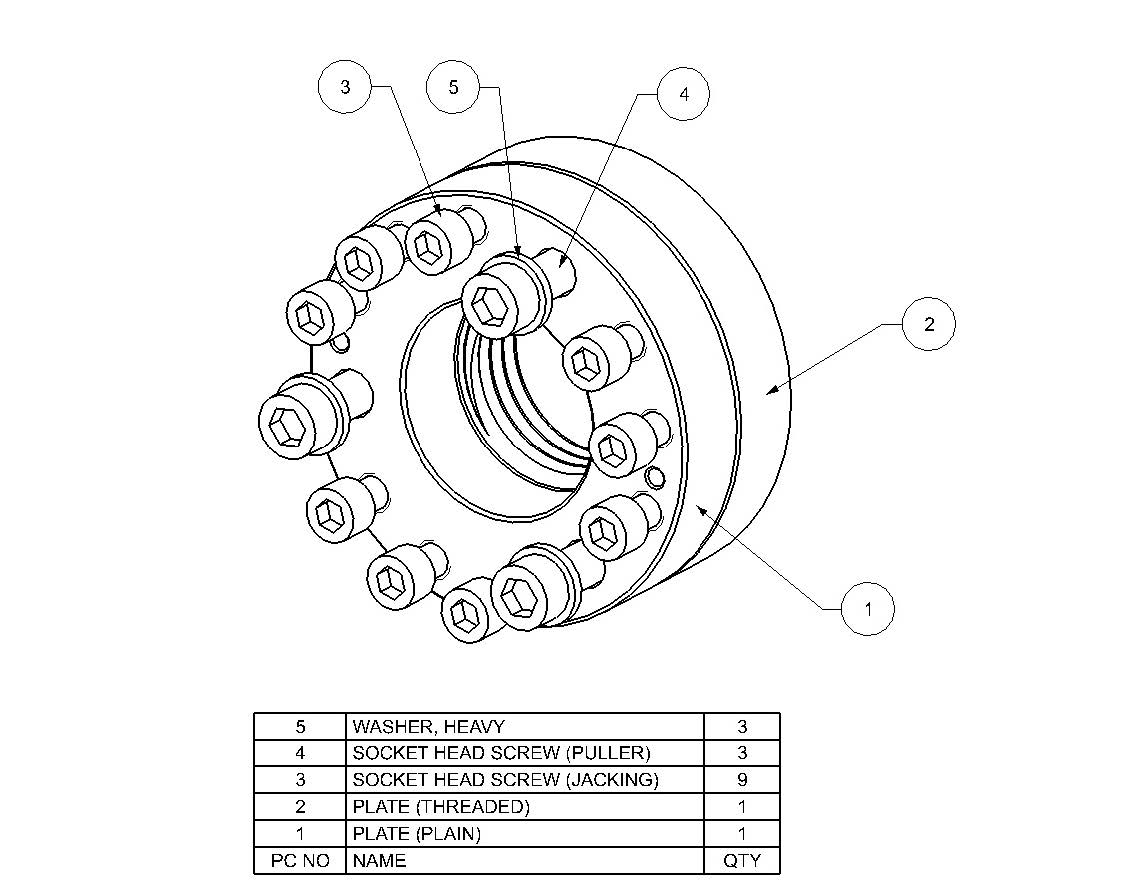

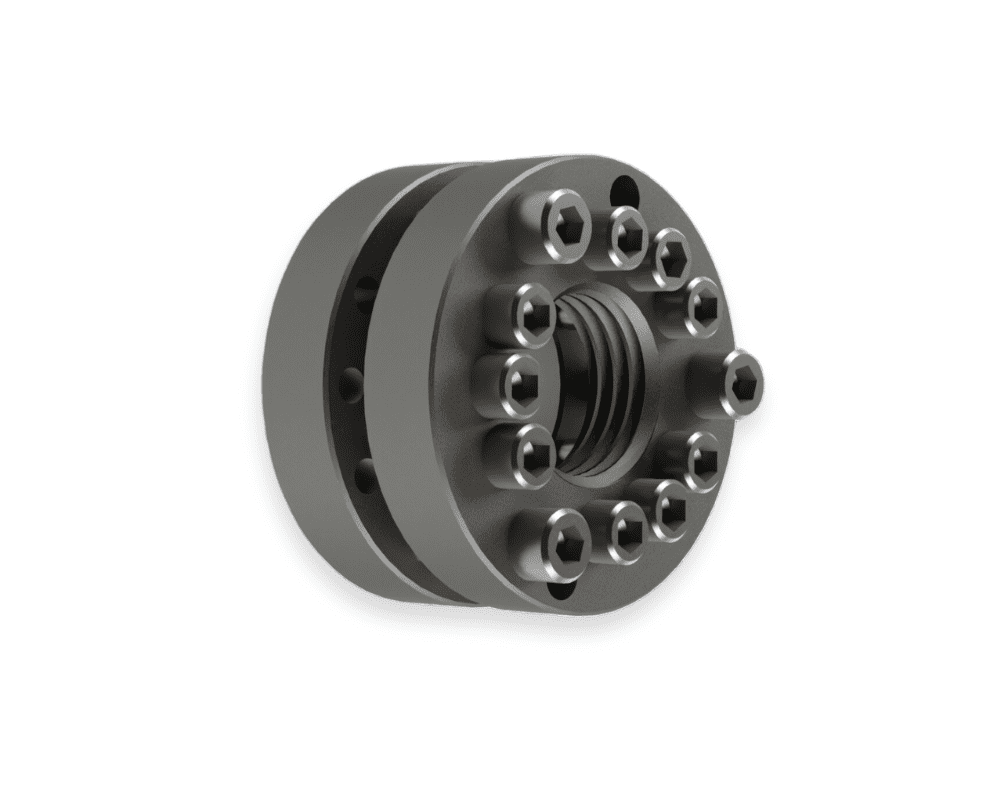

2. Prepare the Puller.

Lubricate the 6 or 9 hex socket jacking screws, depending on your model (Item 3), and install them into the side of the puller with the threaded bore (Item 2). Place the puller onto the shaft thread, ensuring the flat face is against the aft end of the propeller (non-threaded side – Item 1).

3. Align and Secure.

Align the 3 puller bolt holes with the threads at the aft end of the propeller. Install at least one of the larger puller bolts (Item 4), leaving it loose with about 8mm (or 0.30”) clearance. This will help to limit rotation when applying torque in the following steps.

4. Tighten the Screws.

Begin tightening the 6 or 9 hex socket screws (Item 3) in a diagonal pattern. Gradually increase the torque after each sequence until the maximum torque (Table 1) is reached on all screws, ensuring even pressure.

5. Finalise Installation.

Once the screws are fully torqued, release the pressure and remove the puller plates. Fit and lock the propeller nut in place, and cover the puller plates and bolts with preservative oil before storing them back in the case.

1. Initial Steps.

Begin by removing the propeller hut.

2. Prepare the Puller.

Lubricate the 6 or 9 hex socket jacking screws (Item 3) and install them in the side of the puller with the non-threaded bore (Item 1). Place the puller onto the shaft thread, ensuring the flat face is towards the aft end of the propeller (Item 2).

3. Align and Secure.

Align the puller bolt holes with the threads at the aft end of the propeller, leaving approximately 6mm (or 0.25″) clearance between the at end of the propeller hub and the face of the puller plate (Item 2). Install the puller bolts and washers (Items and 4) until they just touch the face of the plate.

4. Tighten the Screws.

Gradually tighten the 6 or 9 hex socket screws (Item 3) in a diagonal pattern, increasing torque evenly after each sequence. The propeller should release from the taper with sufficient force. Ensure not to exceed the maximum torque specified in the manual (Table 1).

5. Stubborn Propellers.

If the propeller does not release, maintain maximum puller force while gently tapping the forward end of the propeller hub with an aluminum drift and hammer. Alternatively, you may use a gas torch to warm the hub between the blades.

6. Finalise Removal.

Once the propeller is released, remove the bolts and puller plates. Cover the plates and bolts with a preservative before storing them in the case.

Adjust the relative pitch of each propeller blade in situ to enhance performance.

VEEM delivers an entirely bespoke design for every propeller that maximises the performance of your vessel.

Contact a local VEEM dealer or distributor for support with purchasing a VEEM Marine Propeller or a VEEM Marine Gyro.

Get a size and price estimate on the spot for your vessel.

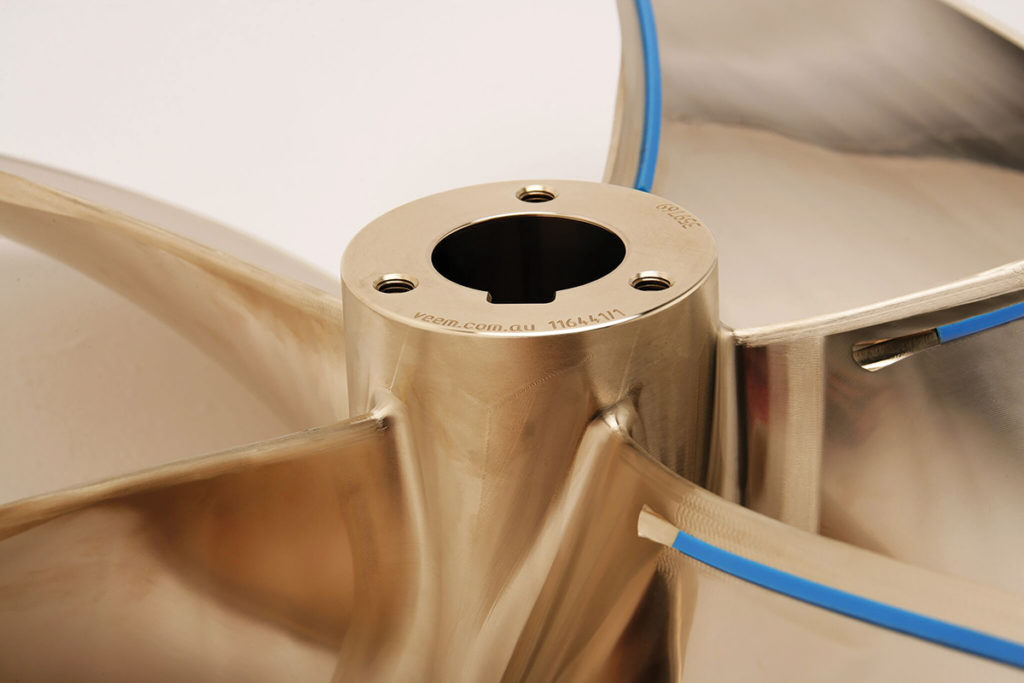

VEEM Marine Propellers are designed better, manufactured to a higher quality and perform higher than any other propeller brand in the world. They are only propellers that are fully CNC machined over every inch, cast without wooden patterns and enable you to change the effective pitch without compromising quality. There is nothing in the world that achieves the same ultimate performance >

VEEM has perfected a cutting-edge system that enables full customisation for every propeller they manufacture. Whether it’s just one propeller or a batch of one thousand, every propeller can be the same or unique.

Unlike competitors, VEEM Marine Propellers are 100% CNC machined to hair thickness accuracy over every square inch of the propeller, including the boss and high BAR overlapping blade propellers. This means we can manufacture exactly what we design and guaranteeing your performance.

VEEM are one of the only propeller manufacturers in the world with the capabilities and expertise to undertake all metal alloying in house. This guarantees all materials are of the highest quality and every propeller is manufactured to perfection.