Propeller Standards (Class 1 vs S-Class vs VEEM)

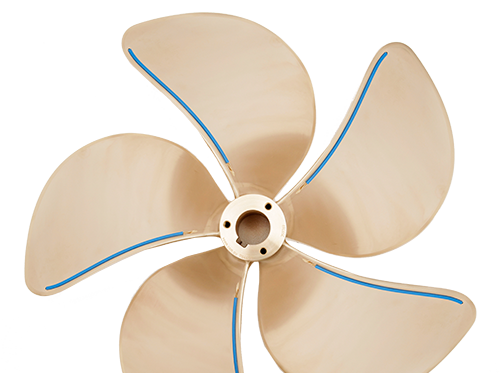

When comparing propeller performance claims across the marine industry, it is important to understand the standards behind each manufacturing method. Class 1 propellers are traditionally hand-profiled, meaning the final shape of each blade is achieved manually. This can lead to variations from blade to blade and noticeable differences in pitch accuracy, surface finish, and vibration levels. ISO S-Class propellers offer a higher standard, with tighter allowable tolerances, but still rely partly on manual craftsmanship and typically achieve accuracy only on selected measurement points rather than across the entire surface.

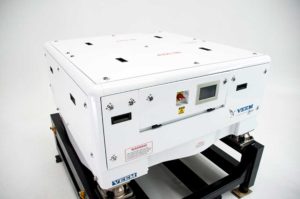

By contrast, VEEM propellers — including the NiBrAl and Extreme ranges — are fully CNC-machined over 100% of the blade and hub surfaces, delivering precision that exceeds S-Class tolerances by design. This approach ensures perfect repeatability, lower vibration, improved efficiency, and consistent performance across every propeller produced. These differences in manufacturing standards explain why VEEM’s sea trial results show such significant gains when compared with Class 1 and even S-Class propellers.

For operators seeking a deeper understanding of propeller classification and tolerances, further information can be found in the ISO 484 standard, which defines the measurement criteria used across the global marine industry.