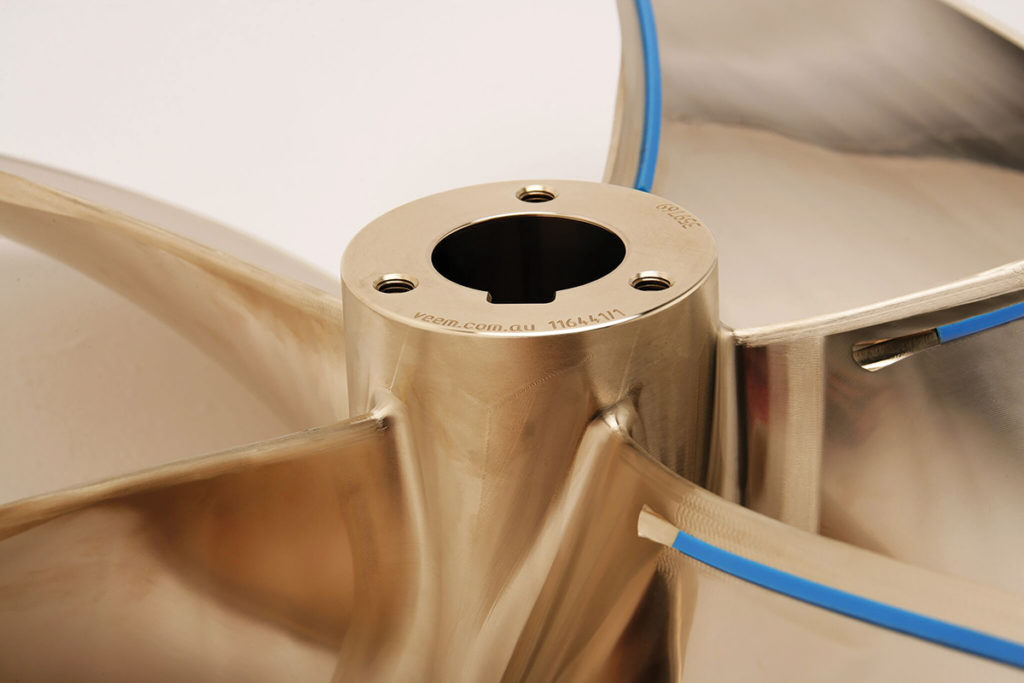

Bespoke Propeller Casting Process

The majority of propellers in the market are cast using wooden patterns. This means most propeller manufacturers can only provide an ‘off the shelf’ range of propellers with limited options to change the principle geometry. These minimal changes don’t always suit the application and they therefore miss out on the optimum design process, which provides the biggest gain in propeller performance and smoothness.

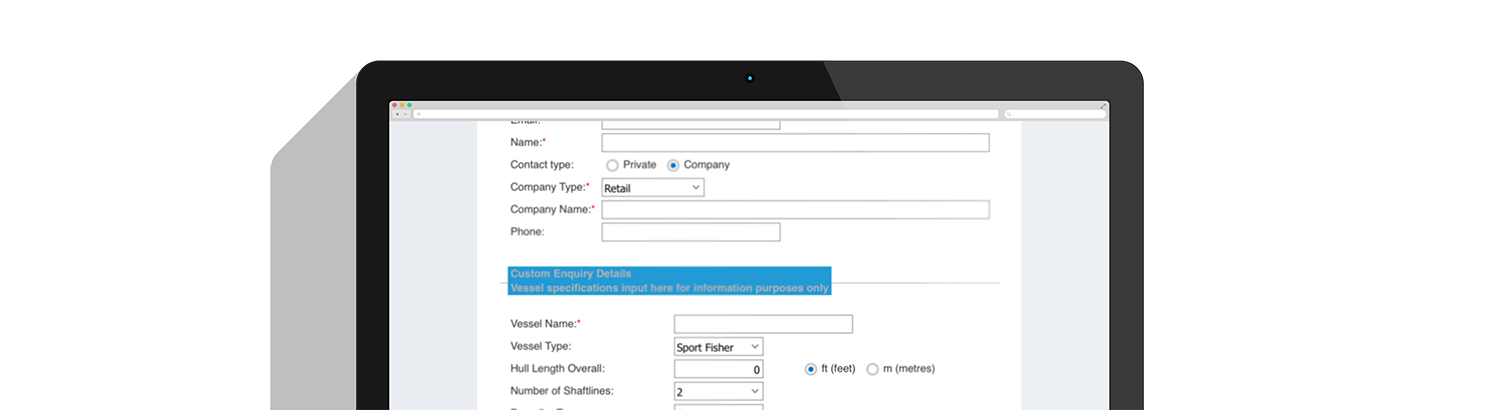

VEEM has pioneered an innovative casting system, ensuring that each propeller they manufacture is tailored to meet specific requirements. Whether it’s just one propeller or a batch of one thousand, every propeller can be different and is produced at the same cost. VEEM’s innovative techniques have allowed for incredible precision when it comes to designing unique propulsion systems for vessels around the world. Our highly-automated robotic foundry process means we can specify exactly what the vessel needs in order to meet its specific performance requirements.